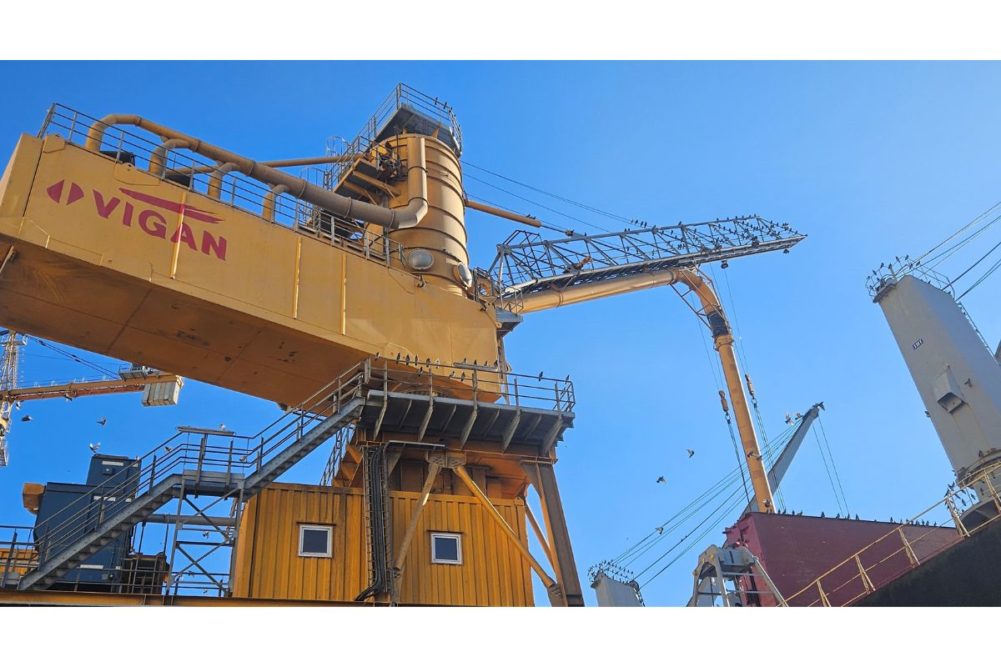

CASABLANCA, MOROCCO — Four years after Vigan’s pneumatic grain unloader, the NIV800, played a critical role in the capacity expansion of the Société des Silos Portuaires (SOSIPO) grain terminal in the Port of Casablanca, the company has been granted a new order as part of the second phase of modernization.

The NIV800 set a global benchmark with its capacity of 800 tonnes per hour in the expansion of ship storage and unloading capacities for the SOSIPO terminal.

“In this pivotal year of 2019, satisfaction was palpable within Vigan, having earned the esteemed trust of SOSIPO to design the first 800 tph pneumatic unloader from Vigan, a true innovative feat,” said Mohamed El Khattabi, sales director at Vigan. “This achievement consolidates our 41 years of successful partnership.”

SOSIPO, a subsidiary of the National Interprofessional Office for Cereals and Legumes (ONICL), manages the cereal silos in the ports of Casablanca, Safi, Agadir and Nador that belong to ONICL.

Four years after the initial expansion, SOSIPO’s confidence in Vigan led to an order for a second 800-tph pneumatic unloading gantry (NIV800), thereby becoming a global reference in the field.

“The technical challenge posed by the first unloader of this magnitude was masterfully overcome through the tenacity of Vigan Engineering’s Research and Development Department and the unwavering trust of SOSIPO,” said El Khattabi.

The newest installation will be the fourth Vigan gantry installed in the port of Casablanca for SOSIPO (the seventh in Morocco) and the second 800 tph pneumatic grain unloader in the world.

“Clients who turn to us undoubtedly seek an energy-efficient and high-performance gantry, even in extreme conditions, as well as a robust and reliable machine,” said El Khattabi. “Vigan Engineering continues its constant commitment to technical innovation, thus meeting the growing demands of our clients and market developments. With particular attention to reducing dust emissions, our predominant choice for pneumatic technology at Vigan has the undeniable advantage of minimizing nuisances. Our systems are designed with hermeticity, incorporating overpressure filters that maintain dust within a closed circuit.”

In an era where environmental concerns take center stage, these considerations are now at the core of industrial projects, said El Khattabi. However, for Vigan, the current trend also leans towards pneumatic machines with increasingly larger unloading capacities. The second 800-tph gantry is a prelude to a promising series, with several contracts for unloading projects of this size currently being finalized worldwide, positioning Vigan as a key player appreciated for its global innovation and performance, he added.