SPRINGFIELD, OHIO, US — Sweet Manufacturing Co. has updated its most popular product line, Silver-Sweet bucket elevators.

After months of research and development, Sweet Manufacturing has redesigned its bucket elevator product line using feedback from end users and dealers.

The new Quality Line Series is designed to convey bulk materials vertically, with capacities ranging from 4,000 to 11,925 bushels per hour. The design enhances all features across the board when compared to the company’s legacy line.

This improved design emphasizes a G140 USA prime steel construction, head and boot lip seals standard, and bigger, heavier-duty access doors, enhancing equipment lifespan and serviceability while reducing assembly time.

“Years of innovation in the material handling industry have created a demand for a wide array of options,” said Chris Smith, vice president of engineering at Sweet Manufacturing. “When designing the Silver-Sweet Quality Line Series, we set out to do three things. First, we wanted to upgrade our offerings to include as standard many of the items our customers have been demanding. Second, we understand that time is money, so we designed the new elevators with ease of installation and serviceability in mind. Finally, we replaced customization with modularity. This will allow us to tailor the elevator to our customers’ current and future needs while maintaining quality and efficiency.”

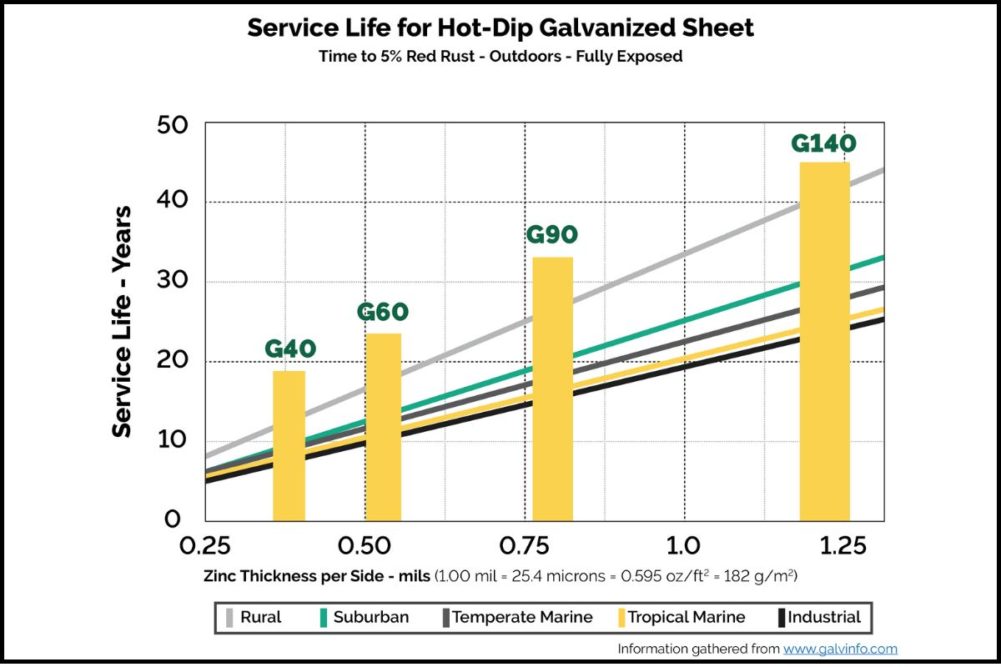

Along with the Silver-Sweet QL Series product release, Sweet Manufacturing is announcing a significant upgrade to its existing product lines. Effective immediately, all Sweet Manufacturing equipment will be constructed using G140 USA Prime Steel compared to its previous G90 construction.

The transition to G140 Galvanized USA Prime Steel will increase the average service life of their equipment by 25% when compared to the industry standard of G90 Steel.