AHRENSBURG, GERMANY — Since the prices and availabilities of wheat are scarcely calculable at present in some regions of the world, many mills are looking for alternatives as a way of cushioning the impact of the cost explosion. In the African continent especially, the idea of using “composite flour” is gaining momentum, said Liezel Huysamen, senior application technologist, southern Africa, for flour improvement specialist Mühlenchemie.

“We are receiving more and more enquiries from customers about how to replace part of the wheat with starch products from local sources,” Huysamen said.

Composite flour is made by blending or mixing varying proportion of non-wheat flour with wheat flour and used for production of leavened or unleavened baked or snack products.

Mühlenchemie is pushing ahead consistently with composite flour as one of the major topics of the future. With the new Compozym product range, mills can respond actively to the increasing challenges and upheavals of the market by including non-wheat crops in the production of their flours. Compozym solutions offer millers a way of maintaining profitability in these unprecedented times in the wheat market.

Why it works in Africa

For the African milling industry, especially, this sustainable approach can open a way of achieving greater independence of the volatile conditions on the global markets, reducing the cost of raw materials and launching new, functional composite flours with a regional touch. In the past, substitutions of this kind usually meant compromising on quality, because wheat has the best baking properties of all cereals due to its special gluten fraction.

“As soon as low-gluten or gluten-free alternatives are used, they change the dough structure, the baking process and the appearance of the products,” Huysamen said, putting the undesirable side effects in a nutshell.

On the other hand, knowing the culinary preferences of the region, Huysamen said the slightly different sensory properties are not a disadvantage, since African consumers are partial to the taste and aroma of maize or cassava, for example.

No addition of vital gluten

Mühlenchemie has responded to the new technical challenges and developed a raw material concept that deliberately excludes the use of vital gluten to keep the cost of flour treatment as low as possible for the mills.

“The strongest lever for optimizing the economic aspects of composite flour lies in fine adjustment of enzyme-based flour treatment,” said Stefan Creutz, Mühlenchemie’s strategic applications development manager, describing the company’s approach to this pioneering work. “In close cooperation with our African team, we carried out numerous rheological analyses and trials in order to achieve the best possible balance in the different flours with application-specific enzyme formulations.”

The tasks involved were highly complex, since each non-wheat flour has different product attributes.

“The high starch content of cassava shortened the shelf life of the bread,” Creutz said. “Certain millet varieties produced a very intensive taste, and in some cases maize flour resulted in a yellowish or granular crumb structure.”

At the start of the project, the technologists repeatedly were confronted with adverse effects on volume, dough stability or the shelf life. But the farther they delved into the subject of composite flour, the more precisely they were able to compensate for the deficiencies of the mixtures. To cover the widest product range, the test series were carried out with baguette, Fino, Ekmek, Roti and Chapati as well as sandwich bread.

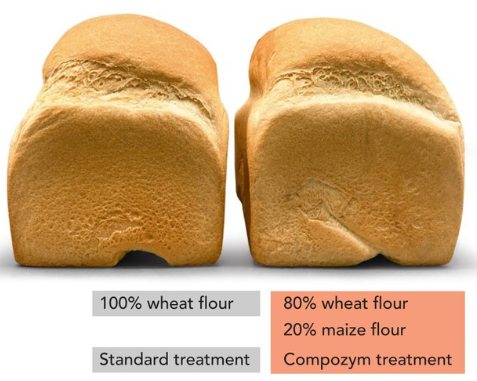

The trials resulted in complex, mixed enzyme systems that permit the inclusion of up to 20% of non-wheat flour without having to compromise on processing characteristics or the quality of the products.

“Compozym offers an excellent means of compensating for the poor viscoelastic properties of the wheat substitutes,” Creutz said.

New-generation product

Beside the basic treatments, the toolbox includes “on-top” applications that specifically promote such attributes as a highly succulent crumb, delayed retrogradation or greater tolerance to long fermentation times. In such cases, Compozym may be combined with products from Alphamalt Fresh or EMCEbest WA ranges.

“Whereas the addition of local non-wheat flours used to be regarded as a compromise, the new generation of composite flour products will be able to assert itself much more confidently,” said Jannes Peemöller, Mühlenchemie’s area sales manager.

Sven Mattutat is a product manager with Mühlenchemie. He may be reached at smattutat@stern-wywiol-gruppe.de.