CHARLOTTE, NORTH CAROLINA, US — REMBE introduced a new and improved EXKOP isolation system that is available for more applications, including ST2 dusts, reduced explosion pressures of up to 2 bar and larger diameters.

The upgraded controllers allow for flexibility as process requirements change.

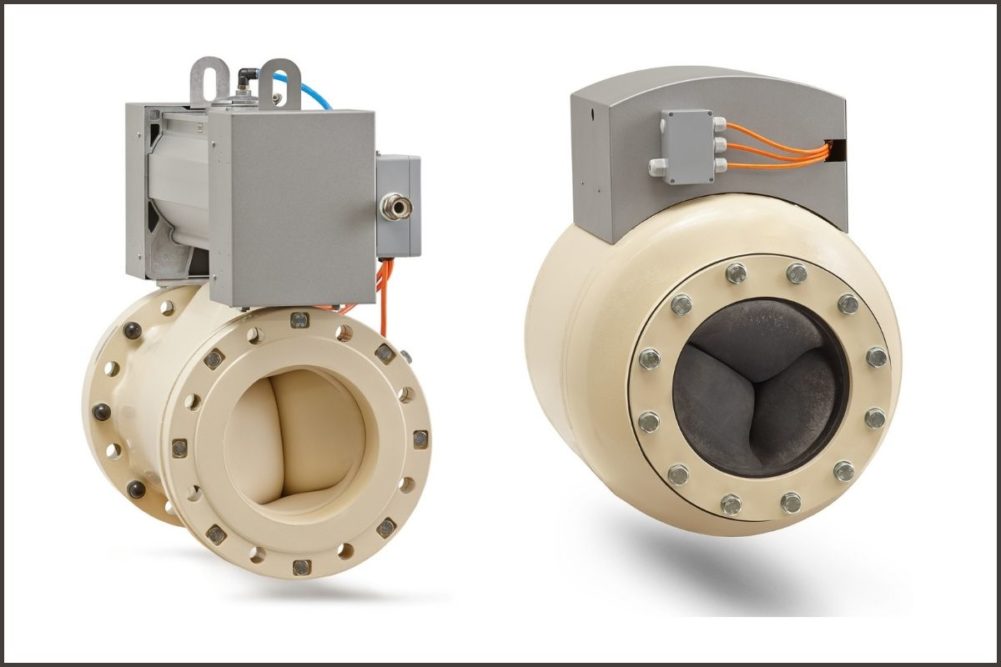

Process equipment is usually connected by pipelines through which, if an explosion occurs, fire and pressure spread very rapidly. REMBE’s EXKOP isolation system, consisting of a control panel, triggering devices and one or more quench valves, can stop this sequence of events.

The integrated elastomer seal within the quench valve closes within milliseconds, triggered by a signal from a burst indicator on a REMBE explosion panel, an infra-red signal, or a pressure sensor. The REMBE EXKOP system is fail-safe and easy to test/reset at the press of a button.