KONYA, TURKEY — Yenar has produced its 100th CNC roll fluting and grinding machine.

The company celebrated the milestone with a gathering of employees in December. Yenar started production of the CNC machine in 2013.

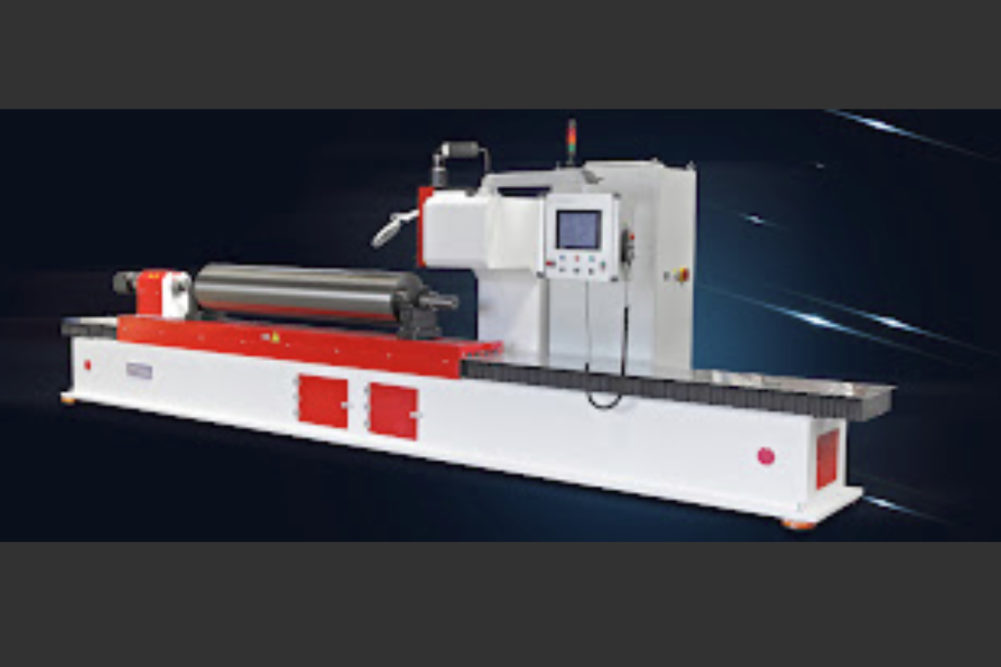

The combined machine is produced in Yenar’s new plant equipped with the latest technology machines and with highest level of quality control.

The major features of the machine includes grinding the roll in the desired profile according to the flow sheet, a mounted crane option, local language support and remote access systems. This model offers the opportunity to flute and grind the rolls up to Ø350 mm and 1.500 mm in length.

This year, Yenar produced 25 roll fluting and grinding machines and 22 sandblasting machines for smooth rolls. The targeted number of 45 different types of machines for 2021 was reached by the end of 2020.

The company offers three sizes of combined fluting and grinding machines, single fluting machines and single grinding machines. Flowing sizes include 350x1,500 mm, 450x2,100 mm and 600x2,100 mm for flour milling, feed milling and oil milling rolls.

Yenar’s combined fluting and grinding machine presents three options for grinding roll types, including cylindrical, camber and chamfer.

For fluting operation, the user only needs to input the flow sheet and software automatically calculates the cutting depth. Remote assistance is available for problem solving.

The sandblasting machine allows a user to reach the requested roughness average on the surface of smooth rolls. The PLC controlled machine has a sand recycling system and vacuum suction with filter to provide a dust-free environment.

Yenar continuously improves its technical infrastructure by making high-cost investments.

“As we have been in our production of rolls for 26 years, we will continue our investments, production and exports in 2022,” Yenar said. “We provide service to our customers not only with our productions but also with our after-sales service. With investments done, our plant is the only production plant for the combined fluting and grinding machines in the world. Selling 100 machines in such a short time shows the trust of our customers to our products. In more than 30 countries, especially in America and Asia, millers easily re-flute, grind and sandblast their rolls by themselves. We would like to thank all our employees who contributed to our milestone 100th machine.”

Yenar seeks to improve the quality and the consistency of the sector by adding new devices and developments. One of these innovations is the RollCare Profile Measurement device. It uses laser technology to check roll profiles on roller mills.

It allows Yenar to compare the roll fluting profile with the theoretical one, allowing plant operators to plan the optimum maintenance plan. The rollCare does not require any adjustment and automatically overlaps both profiles and reports back the required value.

Operators can check what are the sharp and dull angles, land, how many flutes are on per cm, depth of the flutes and how the flutes wear. In addition, you can put it on the fluting machine while actively fluting and check the flutes status, providing a system to check whether the land and depth are correct or still need to be fluted.

This device is equipped with wireless so there’s no need to carry a laptop around.

Yenar continues to develop machinery not only for flour mills sector but also for the oil milling sector. The latest innovation of its R&D center is the flakeCare mobile turning and grinding machine. The flakeCare machine allows refurbishment of the flaking rolls surface without removing the rolls. This machine is custom designed as the linkage points for each machines’ manufacturer is different.